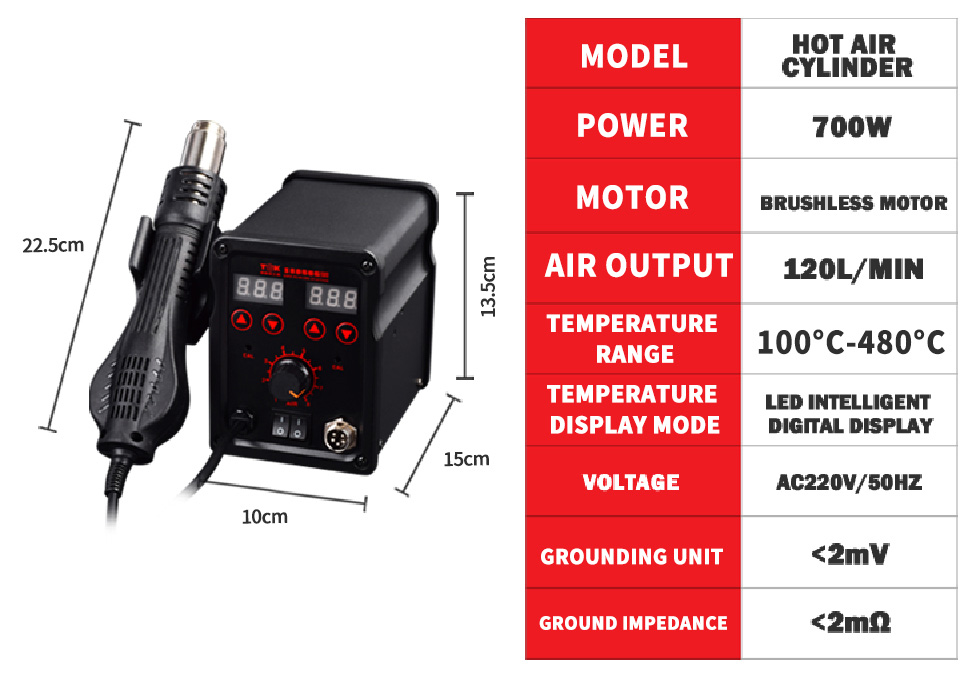

| Input voltage | AC220V |

| Rated power | 700W |

| Air flow | 120L/min |

| Temperature range | desoldering Station:00-480ºC, digital display, button adjustment |

| Heating time | Normal temperature rises to 350ºC<45 seconds |

| Temperature stable value | ±5ºC |

| Temperature deviation | ±10ºC CAL hole fine adjustment Calibration temperature |

| Soldering iron tip to ground potential | <2mV |

| Soldering tip resistance to ground | <2Ω |

| Power cord specification | 3Px0.5mm²x1.6m Product suffix |

| Handle wire specification | 8 cores outer silicone inner material, length 1.2 meters |

| Desoldering station handle | 858 special handle |

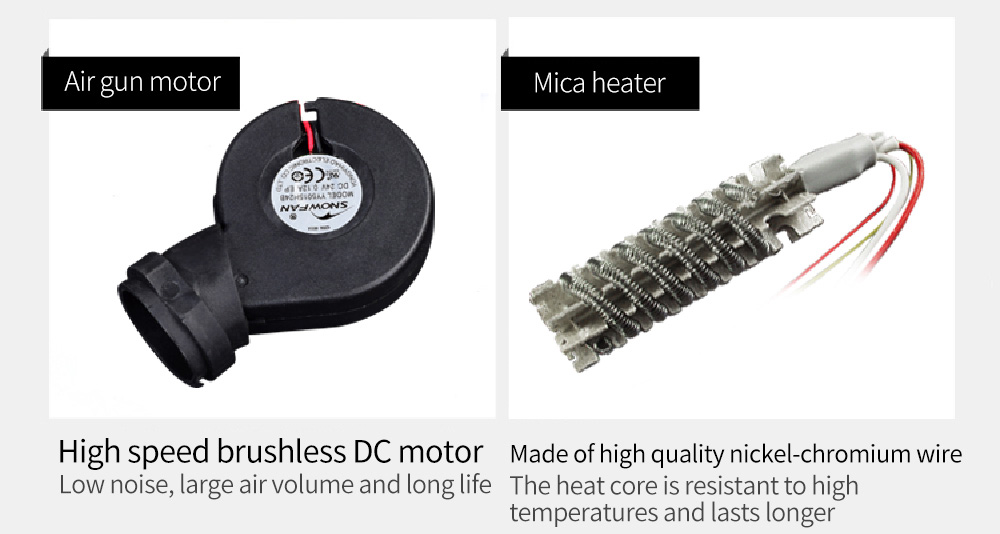

| Heating core | 858 dedicated heating core (mica bracket) |

| Transformer | Pure copper transformer |

| Circuit structure | MCU control PID temperature control |

| Feature | LED digital display, clear at a glance, easy to manage |

| Fault self-checking Heater damage LED screen display prompt |

| Adopt high-speed brushless fan, high-power heating core, large air volume, soft air outlet, and rapid heating |

| Standby cooling function (sleep), greatly extending life |

| Desoldering for Surface Mount Parts |

1. Iron temperature: it will reduce function when temperature is high, so please low temperature. With strong recover temperature function. Lower temperature weld enough and protect the temperature sensitive components. 2. Clean-up: clean soldering iron with cleaning sponge. After welding, iron oxide and iron carbide welding damage it, heat conduction will decrease. Please clean iron oxide to prevent damage and low the temperature.

1. Iron temperature: it will reduce function when temperature is high, so please low temperature. With strong recover temperature function. Lower temperature weld enough and protect the temperature sensitive components. 2. Clean-up: clean soldering iron with cleaning sponge. After welding, iron oxide and iron carbide welding damage it, heat conduction will decrease. Please clean iron oxide to prevent damage and low the temperature.

3. When not use: please keep lower temperature when don’t use it, high temperature will generate oxide and reduce thermal conductivity function. 4. After using: clean solder iron after using, plate tin to prevent oxidation.

3. When not use: please keep lower temperature when don’t use it, high temperature will generate oxide and reduce thermal conductivity function. 4. After using: clean solder iron after using, plate tin to prevent oxidation.